ʻO ke kumukūʻai haʻahaʻa loa e mālama ana i ka ikehu Mea hoʻohana-aloha Haʻahaʻa Mālama ʻakomi Busbar ʻoki a me ka mīkini kuʻi Busbar mīkini hana Busbar

Ua maopopo iā mākou me nā hana like, e lawe mai ka ʻoihana ma waena o mākou i nā pono like. Hiki iā mākou ke hōʻoia iā ʻoe i ka huahana maikaʻi loa a me ke kumukūʻai ikaika no ke kumukūʻai haʻahaʻa Energy-Saving User-Friendly Low Maintenance Automatic Busbar Cutting and Punching Machine Busbar Processing Machine, No ka mea, noho mākou ma kēia laina ma kahi o 10 mau makahiki. Loaʻa iā mākou ke kākoʻo mai nā mea hoʻolako maikaʻi loa ma ke ʻano maikaʻi a me ke kumukūʻai. A ua kāpae mākou i nā mea hoʻolako me ka maikaʻi ʻole. I kēia manawa, ua hui pū nā hale hana OEM he nui me mākou.

Ua maopopo iā mākou me nā hana like, e lawe mai ka ʻoihana ma waena o mākou i nā pono like. Hiki iā mākou ke hōʻoia iā ʻoe i ka huahana maikaʻi loa a me ke kumukūʻai hoʻokūkū noMīkini Hana Busbar a me ka Mīkini Kuʻi ʻoki Busbar, I kēia manawa, ke ulu mau nei kā mākou pūnaewele kūʻai aku, e hoʻomaikaʻi ana i ka maikaʻi o ka lawelawe e hoʻokō i ka noi a ka mea kūʻai aku. Inā makemake ʻoe i kekahi huahana, e ʻoluʻolu e kelepona mai iā mākou i kēlā me kēia manawa. Ke kakali nei mākou i ka hoʻokumu ʻana i nā pilina ʻoihana holomua me ʻoe i ka wā e hiki mai ana.

Nā kikoʻī huahana

He lako hana ʻoihana ʻo GJCNC-BP-60 i hoʻolālā ʻia e hana i ka busbar me ka maikaʻi a me ka pololei.

I ka wā e hana ana, hiki i kēia lako ke pani koke i nā clamps, he mea kūpono loa ia no ka busbar lōʻihi. Me kēlā mau make hana i loko o ka waihona mea hana, hiki i kēia lako ke hana i ka busbar ma ke kuʻi ʻana (puka poepoe, puka oblong a pēlā aku), embossing, shearing, grooving, ʻokiʻoki i ke kihi filleted a pēlā aku. E hāʻawi ʻia ka ʻāpana hana i hoʻopau ʻia e ka conveyor.

Hiki i kēia lako ke kūlike me ka CNC bender a hana i ka laina hana hana busbar.

ʻAno Nui

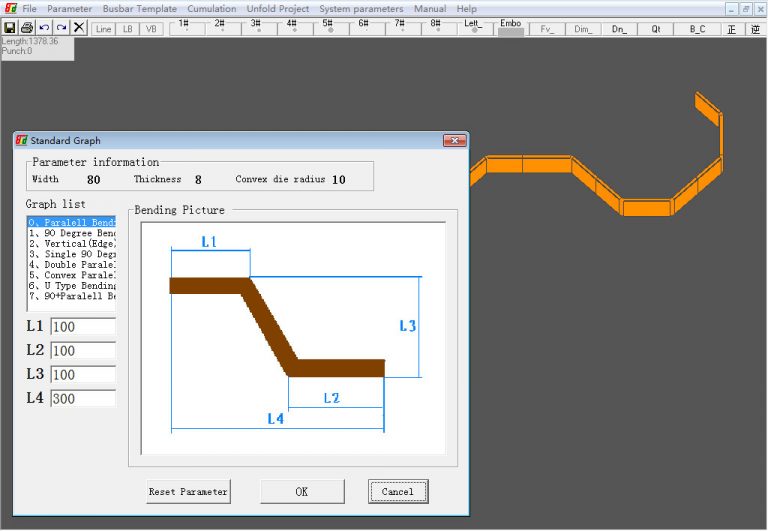

Polokalamu papahana / GJ3D

He polokalamu hoʻolālā kōkua kūikawā ʻo GJ3D no ka hana ʻana i ka busbar. Hiki iā ia ke hoʻolālā aunoa i ke code mīkini, helu i kēlā me kēia lā i ka hana ʻana, a hōʻike iā ʻoe i ka hoʻohālike o ke kaʻina holoʻokoʻa e hōʻike maopopo ana i ka hoʻololi ʻana o ka busbar i kēlā me kēia ʻanuʻu. Ua hana kēia mau huapalapala i mea maʻalahi a ikaika hoʻi e pale aku i ke code manual paʻakikī me ka ʻōlelo mīkini. A hiki iā ia ke hōʻike i ke kaʻina holoʻokoʻa a pale pono i ka hoʻonele ʻana i nā mea i hana ʻia e ka hoʻokomo hewa ʻana.

No nā makahiki i hala aku nei, ua alakaʻi ka ʻoihana i ka hoʻopili ʻana i ke ʻano hana kiʻi 3D i ka ʻoihana hana busbar. I kēia manawa hiki iā mākou ke hōʻike iā ʻoe i ka polokalamu hoʻokele a me ka hoʻolālā cnc maikaʻi loa ma ʻAsia.

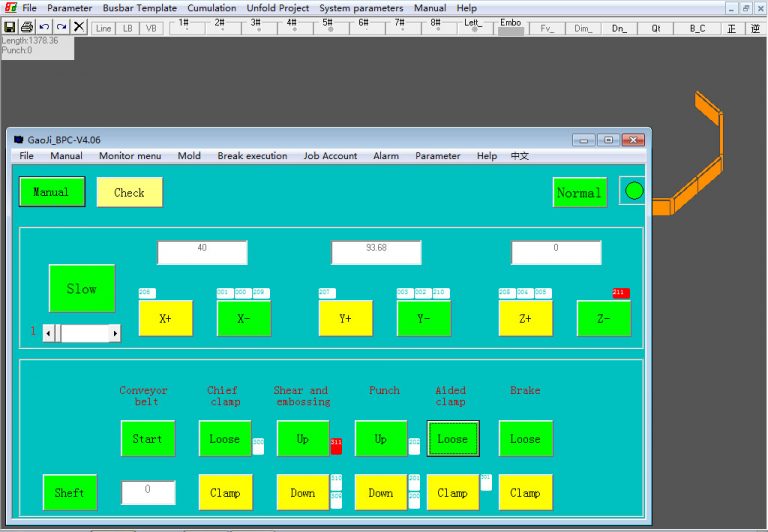

Ka pilina kanaka-kamepiula

I mea e hōʻike ai i ka ʻike hana maikaʻi aʻe a me ka ʻike pono hou aku. Loaʻa i ka lako kahi 15” RMTP ma ke ʻano he pilina kanaka-kamepiula. Me kēia ʻāpana hiki iā ʻoe ke loaʻa ka ʻike maopopo o ke kaʻina hana holoʻokoʻa a i ʻole kekahi alarm e hiki mai ana a kaohi i nā lako me ka lima hoʻokahi.

Inā pono ʻoe e hoʻololi i ka ʻike hoʻonohonoho o ka lako a i ʻole nā palena make kumu. Hiki iā ʻoe ke hoʻokomo i ka lā me kēia ʻāpana.

Nā Hana Mīkini

I mea e hana ai i kahi ʻano mechanical paʻa, pono, pololei a lōʻihi ke ola, koho mākou i ka wili pōpō pololei kiʻekiʻe, ke alakaʻi linear pololei na Taiwan HIWIN a me ka ʻōnaehana servo na YASKAWA me kā mākou ʻōnaehana clamp ʻelua kū hoʻokahi. Hoʻokumu kēia mau mea a pau i kahi ʻōnaehana hoʻoili maikaʻi e like me kou makemake.

Hoʻomohala mākou i kahi polokalamu hoʻololi ponoʻī i mea e ʻoi aku ai ka maikaʻi o ka ʻōnaehana clamp, ʻoi aku hoʻi no ka hana ʻana i ka busbar lōʻihi, a hiki nō hoʻi ke hōʻemi nui i ka hana a ka mea hoʻohana. E hoʻokumu i ka waiwai hou aku no kā mākou mea kūʻai aku.

ʻElua ʻano:

GJCNC-BP-60-8-2.0/SC (ʻEono kuʻi ʻana, kahi ʻokiʻoki, kahi kaomi ʻana)

GJCNC-BP-60-8-2.0/C (ʻEwalu kuʻi ʻana, kahi ʻokiʻoki)

Hiki iā ʻoe ke koho i nā ʻano hoʻohālike āu e pono ai

Hoʻokuʻu aku i ka hoʻopili ʻana

Ua maopopo iā mākou me nā hana like, e lawe mai ka ʻoihana ma waena o mākou i nā pono like. Hiki iā mākou ke hōʻoia iā ʻoe i ka huahana maikaʻi loa a me ke kumukūʻai ikaika no ke kumukūʻai haʻahaʻa Energy-Saving User-Friendly Low Maintenance Automatic Busbar Cutting and Punching Machine Busbar Processing Machine, No ka mea, noho mākou ma kēia laina ma kahi o 10 mau makahiki. Loaʻa iā mākou ke kākoʻo mai nā mea hoʻolako maikaʻi loa ma ke ʻano maikaʻi a me ke kumukūʻai. A ua kāpae mākou i nā mea hoʻolako me ka maikaʻi ʻole. I kēia manawa, ua hui pū nā hale hana OEM he nui me mākou.

Kumukūʻai haʻahaʻa loaMīkini Hana Busbar a me ka Mīkini Kuʻi ʻoki Busbar, I kēia manawa, ke ulu mau nei kā mākou pūnaewele kūʻai aku, e hoʻomaikaʻi ana i ka maikaʻi o ka lawelawe e hoʻokō i ka noi a ka mea kūʻai aku. Inā makemake ʻoe i kekahi huahana, e ʻoluʻolu e kelepona mai iā mākou i kēlā me kēia manawa. Ke kakali nei mākou i ka hoʻokumu ʻana i nā pilina ʻoihana holomua me ʻoe i ka wā e hiki mai ana.

Nā Kūlana ʻenehana Nui

| Ana (mm) | 7500*2980*1900 | Kaumaha (kg) | 7600 | Palapala hōʻoia | CE ISO | ||

| Mana Nui (kw) | 15.3 | Anakahi Hoʻokomo | 380/220V | Puna Mana | ʻO ka hydraulic | ||

| Ka ikaika hoʻopuka (kn) | 500 | Ka wikiwiki o ke kuʻi ʻana (hpm) | 120 | ʻAxis Mana | 3 | ||

| Ka nui o ka mea nui loa (mm) | 6000*200*15 | Nā Make Kuʻi Max | 32mm (Mānoanoa o ka mea ma lalo o 12mm) | ||||

| Ka wikiwiki o ka wahi(ʻaoʻao X) | 48m/min | Hahau o ka Paukū Punching | 45mm | Ka hana hou ʻana i ke kūlana | ±0.20mm/m | ||

| Kaha Loa(mm) | ʻAki XʻAki YʻAki Z | 2000530350 | Ka nuiofMake | Kuʻi ʻanaʻokiʻokiKe kālai ʻana | 6/81/11/0 | ||

Hoʻonohonoho ʻana

| Nā ʻĀpana Mana | Nā ʻĀpana Hoʻoili | ||

| PLC | ʻOMRON | Alakaʻi laina pololei | Taiwan HIWIN |

| Nā mea ʻike | ʻO ka uila Schneider | ʻO ka wili pōpō pololei (moʻo 4) | Taiwan HIWIN |

| Pihi Mana | ʻOMRON | Ke kākoʻo ʻana i ka wili pōpō | NSK Kepanī |

| Pale Hoʻopā | ʻOMRON | Nā ʻĀpana Hydraulic | |

| Kamepiula | Lenovo | Kiwikā Uila Malemake kiʻekiʻe | Ikalia |

| Mea Hoʻokaʻaʻike AC | ABB | Paipu kaomi kiʻekiʻe | Italia MANULI |

| Mea haki kaapuni | ABB | Pamu kaomi kiʻekiʻe | Ikalia |

| Motika Servo | YASKAWA | ʻO ka polokalamu hoʻomalu a me nā polokalamu kākoʻo 3D | GJ3D (polokalamu kākoʻo 3D i hoʻolālā ʻia e kā mākou hui) |

| Mea hoʻokele Servo | YASKAWA | ||